EARLY

WARNING

Freezing

rain, ice, snow and deicers, as well as freeze/thaw temperature cycles have

the potential to wreak havoc on concrete surfaces if left unchecked.

Precautionary measures such as repairing and sealing cracks and damaged

concrete surfaces are cost-effective solutions homeowners can do themselves

to prevent expensive replacement projects in the future.

Here are

some tips on what to look for now before winter arrives:

Sealers,

such as QUIKRETE

Acrylic Concrete Cure & Seal - Satin Finish, offer a highly water

resistant coating that protects the surface from cold weather freeze and

thaw cycles — a common cause of surface cracking and spalling over time. Click

here for more project ideas and step-by-step instructions.

Project Tip: Mortar Repair Made Easy

Damaged

mortar can be unsightly. Minor cosmetic repairs to mortar can be made on

any type of brick walls, and making such repairs is easier than many

homeowners realize – all you need is a caulk

gun and the right repair material.

A sanded

acrylic mortar repair caulk - such as QUIKRETE

Mortar Repair – will give the appearance of mortar in texture and color

and is a more easily undertaken project for homeowners who are nervous

about mixing mortar. The caulk's sanded acrylic formula adheres to brick,

block, stone and concrete surfaces, and the caulk tube's square applicator

tip is designed to smooth mortar joints during application of the caulk.

Before

applying, make sure joints are clean, dry and free of grease, dust or loose

particles, and remove all loose mortar from the joint. Apply the caulk by

pushing the cartridge tip over the surface and forcing a bead of caulking

into the opening. Do not apply any thicker than 3/8 inch in one

application. Excess caulk can be wiped off with a damp cloth.

For more

project ideas and information on concrete maintenance and repair, check out www.quikrete.com.

Q&A: How can I color my concrete wall?

My in

ground pool is close to the house foundation along one side of the pool.

The foundation is swirled gray concrete, and the "view" of the

wall when we are in the pool is unsightly. What product can I use to color

the wall (preferably blue)?

Exterior

coatings near a pool need to be more durable than conventional paints. We

generally recommend a permanent, cementitious coating. We would recommend

using QUIKRETE

QUIKWALL Surface Bonding Cement with the addition of QUIKRETE

Liquid Cement Colors (brown to red) or Liquid Stucco & Mortar

Colors, which includes 20 pastel colors from champagne to mocha &

charcoal.

If blue

is a must-have, we recommend one of the professional grade QUIKRETE

Coatings. Whether you use a coating or QUIKWALL, the existing wall

should first be pressure washed with a 3500 psi pressure washer to remove

all loose material, dirt and paint. It is best to prepare the surface and

apply a small trial patch of the new coating to assure satisfaction. Also

note that color will appear different wet vs. dry, and vary with sun and

shade and nearby reflective surfaces during the day.

The most

suitable decorative coating for harsh environments is QUIKRETE

Epoxy Garage Floor Coating. This two-part epoxy product is designed to

withstand the rigors of garage use and beyond, and is available in several

shades of blue special ordered from leading home improvement stores. While

designed for horizontal surfaces, QUIKRETE

Epoxy Garage Floor Coating has been shown to withstand the rigors of

vertical applications.

Click

here for more information on detailed surface preparation and

application instructions.

|

In this Issue

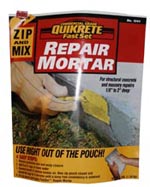

QUIKRETE Zip & Mix Repair Mortar

QUIKRETE

Zip & Mix Repair Mortar is a multi-purpose repair mortar uniquely

packaged to allow the product to be mixed in its pouch, eliminating the

need for a pail. The fast-setting, polymer modified repair mortar is

specifically formulated to make structural repairs to any concrete, masonry

or stucco surface.

To mix,

unzip the enclosure and break through the protective seal. Then, add 10

ounces (or 1 1/4 cup) of water to the mortar, remove excess air from the

package and knead thoroughly. Once mixed, unzip the pouch and apply the

repair material with a putty knife or a mortaring trowel. QUIKRETE

Zip & Mix Repair Mortar does not require any bonding adhesive and

can be applied to structurally sound concrete that has been dampened.

The

mortar's unique properties allow the material to be sculpted during

application. With 20 minutes of working time, the repair mortar is ideal

for vertical or horizontal repairs ranging from feather edge to two inches

deep, including concrete cracks, curbs, sewers, retaining walls, decorative

moldings, bridge columns and other industrial applications.

QUIKRETE

Zip & Mix Repair Mortar will achieve 4,500 psi.

|

Need more know-how? Check out the QUIKRETE Guide to Concrete. Featuring step-by-step descriptions, full-color, photography, quantity calculators and helpful hints and insights for dozens of concrete, masonry and stucco projects.